What Is A Knitting Machine Sponge Bar And Where Is It Located?

Flat bed knitting machines use a sponge bar to hold the needles in place as the carriage moves back and forth. It is about 3/8″ wide and runs the whole length of the bed. Sometimes this bar is referred to as the needle retaining bar. Many ribbers also require one, although some use a bar without any foam, such as in the Brother KR850 standard gauge ribber.

When the sponge bar goes bad, so will your knitting. Stitches may drop for no reason or the carriage might jam, getting its underside caught on needles at the wrong height. When my machines act up, the sponge bar is the first place I look.

Your needles can tell you how your sponge bar is doing. Depending on the machine, the needles will react differently when the bar starts to disintegrate.

When the foam is dead in a standard gauge machine, there is nothing to hold the needles down. They will pop up in their channels which can cause the carriage to jam and needles to bend.

When the foam is dead in a standard gauge machine, there is nothing to hold the needles down. They will pop up in their channels which can cause the carriage to jam and needles to bend.

When the foam is dead in a bulky machine, the needles become loose and sloppy. They don’t pop up like a standard gauge machine.

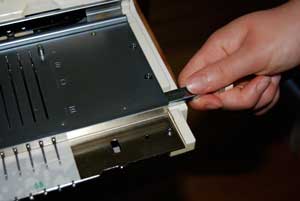

To visually check your bar’s condition, you will need a pusher to get it out. I like to use a bamboo spear like a chop stick. It’s long and won’t scratch any plastic. A screwdriver will also work.

To visually check your bar’s condition, you will need a pusher to get it out. I like to use a bamboo spear like a chop stick. It’s long and won’t scratch any plastic. A screwdriver will also work.

From either side of your machine, locate the end of the sponge bar near the front of the machine.

Gently push with the stick until enough of the bar protrudes on the opposite side to be pulled by your hand.

Gently push with the stick until enough of the bar protrudes on the opposite side to be pulled by your hand.

As you remove the bar, notice that the metal side is up.

This is IMPORTANT! The bar must be installed with the metal side up.

Turn the bar over and look at the foam.

Turn the bar over and look at the foam.

Is it flat or does the sponge material slowly expand? If flat, it is dead and needs to be replaced.

Here is a comparison of a dead sponge bar and one that still has some life left.

To reinstall the bar, begin at either side. With the metal side up, push down on the needles so the foam rides on top. Continue down the length of the bed, pushing down needles and sliding in the bar.

To reinstall the bar, begin at either side. With the metal side up, push down on the needles so the foam rides on top. Continue down the length of the bed, pushing down needles and sliding in the bar.

Next post, we’ll take apart and clean out an old sponge bar. Later in this series, we’ll make a new bar from commonly available sheet foam and fusible interfacing.

Continue on to Part 1 – How to make a sponge bar

Related Posts

- How To Make A Knitting Machine Needle Retainer Sponge Bar Part 2: Cut and Glue Foam

- How To Take Apart A Brother Punch Card Knitting Machine

- How To Make A Knitting Machine Needle Retainer Sponge Bar Part 1: Remove The Old And Clean For New

- How To Make A Knitting Machine Needle Retainer Sponge Bar Part 3: Fuse Interfacing, Tape Ends, And Reinstall

- How To Buy A Used Knitting Machine – Gauge and Parts

July 14, 2008

21 comments

Good tutorial! I also did a lesson on the topic of changing a sponge strip for the Brother KX 35o. It’s a little different process since the sponge doesn’t sit on a metal bar. Your readers may be interested in that tutorial as well. It’s on my blog

Thank you so much for not only showing how to take out the needle bar, but how to check if it is still good. I love doing things myself so I printed out the steps 1 through 3 for making the new sponge repair and am making myself a looseleaf notebook to go with the new(old) bulky knitter I just received yesterday. Bless you from the bottom of my heart!!!

I AM HAVING TROUBLE SETTING MY RIBBER UP PROPERLY

I HAVE A STANDARD GAUGE BROTHER MACHINE 940

I FIND THE SPACE BETWEEN THE TOP BED AND RIBBER IS TOO WIDE

AND ITS HARD TO GET DOWN AFTER USING IT

SO I THINK ITS SET UP WRONG

DO YOU OR ANY ONE KNOW WHERE I AM GOING WRONG

THANKYOU

I bought my daughter a Brother KH836 knitting machine. We replaced the sponge bar and since then the needles are not sitting correctly. Have we done something wrong?

When you put the sponge bar back in, the metal side is up and the sponge part rests on the top side of all the needles. I’d check to make sure it was installed correctly.

I have a brother 950i, I used weather stripping 3/8 x 3/8 and it went in beautifully but now my patterner will not work. It pushes all the needles forward instead of just my pattern needles. Have any ideas?

My lace carriage jams…in fact I have never gotten it to work. I followed your terrific instructions found my sponge bar was in really bad shape, and made a new one. The needles all stay low now instead of popping up and I am thrilled. But, my lace carriage still won’t work…it still seems to be hitting something, probably the needles and bends them. Do you have any other ideas of what could be causing this?

Your site is the best!

We have a group of young ladies in our church who are learning how to knit, and your site is helping us. God bless you all!

need help figuring out why my yarn keeps jamming in my machine. I use thin string type yarn and it works fine. When I put in 4 ply yarn it starts to jam. I have adjusted the stitch size up to 10 to see if that loosens up the tension. Hard to bring the carriage across… HELP!!

Hi I made a sponge bar and by mistake I have put it back with no covering on the weather strip. will this do damage and should I remove it and start again ? The needles seem ok but im not sure if ive done any harm. regards Debbie

Hello:

The encourage and information on your website is excellent and I wish you all the best, You are a wonderfull person. Thank you, Thank you.

Ruth

[…] member). In search of the spongebar I was brought to a blog called Knittsings where she did a post about checking and replacing this curious object. Following the instructions, I pulled my […]

Hi,

I just replaced the spongebar in a bulky singer 155, and the needles are touching the bed int the front, but it looks like there is space in between the needles and the bed in the back of the needles with the needles pushed out, is that okay?

Betty

Hi.

Thank you for your info and website!! This is one of my favorite websites. Without you, this would not be possible!!! ***

A friend of mine found out that I had wanted a knitting machine forever and never had one. One of Life’s dreams!! So on Friday, she decided to give me hers that was in her attic. It is a Singer 700 like the one you are selling on your website.

*** Through your website, I learn to troubleshoot and fix the problem of jamming…

1. Found what is a Sponge bar, to troubleshoot it, and then fix it.

2. And to Clean the machine which was in really great shape..

I have had the machine for 4 days!! Yeahoo!!! Today I made my first swatch by following the manual! 🙂 lol!!

Thank you so much for sharing this information!!

Your newest friend and fan!!

Tracy

You have no idea what a wonderful tutorial you have. I bought my Toyota KS901 back in the 80’s – put it away while I worked and raised my family. Now that I brought it out of hybernation, I am having trouble finding out what the problem was until I took out the sponge bar. egads, that is it. I will be working with it to get it up and running again. What a Godsend you are. Thank you, Thank you, Thank you.

I recently purchased a second hand Toyota KS901 knitting Machine which was

in great condition for its age with most of the accessories included. On returning home and setting the machine up for knitting only to discover that there is no needle retaining bar( sponge bar) inserted in the machine. I have scoured the internet to try and obtain one of these but to no avail, can you help me to find this bar or can you advise if there is sponge bar compatable with this machine. Many Thanks W Muir

Wonderful instructions.. used weatherstripping and fixed one of my LK100 machines and have enough left to do the other one too. I had no idea there was a sponge bar in them, and when the needles started jamming, I was afraid they were

beyond repair. Found it a little difficult putting the sponge back in as I tried to slide it under the needles and it did not slide easily. In the end I took out all the needles and finally mastered the technique of getting them down through one slot and up through the other one. I tried knitting a little swatch and it works fine now.

Thank you for all the helpful info

Hi there, just read your tutorial about replacing foam bar, but my k100 empisal machine has no foam inside the sponge bar and I ave been knitting with it just fine. Are there some machines that don’t require the sponge? Many thanks

I replaced my sponge bar foam, using your directions, easy as could be. thank you But now my cariage hangs up , i have messed up 5 needles, what did i do wrong when replacing the sponge bar? i put the metal side up, everything went real well, i sure would appricate it if you would help me, thanks

I’ve just bought a used Brothers 890. I’ve had it cleaned,and tuned up with a pro. I’ve never seen it attached to it’s stand. Could anyone post a pic of their machine attached to the rotating bar of their stand? Thanks Signora

Hi, I have a electronic KH940 my lace carriage gets stuck on the needles , I cant move it at all, could someone give me some advice lease